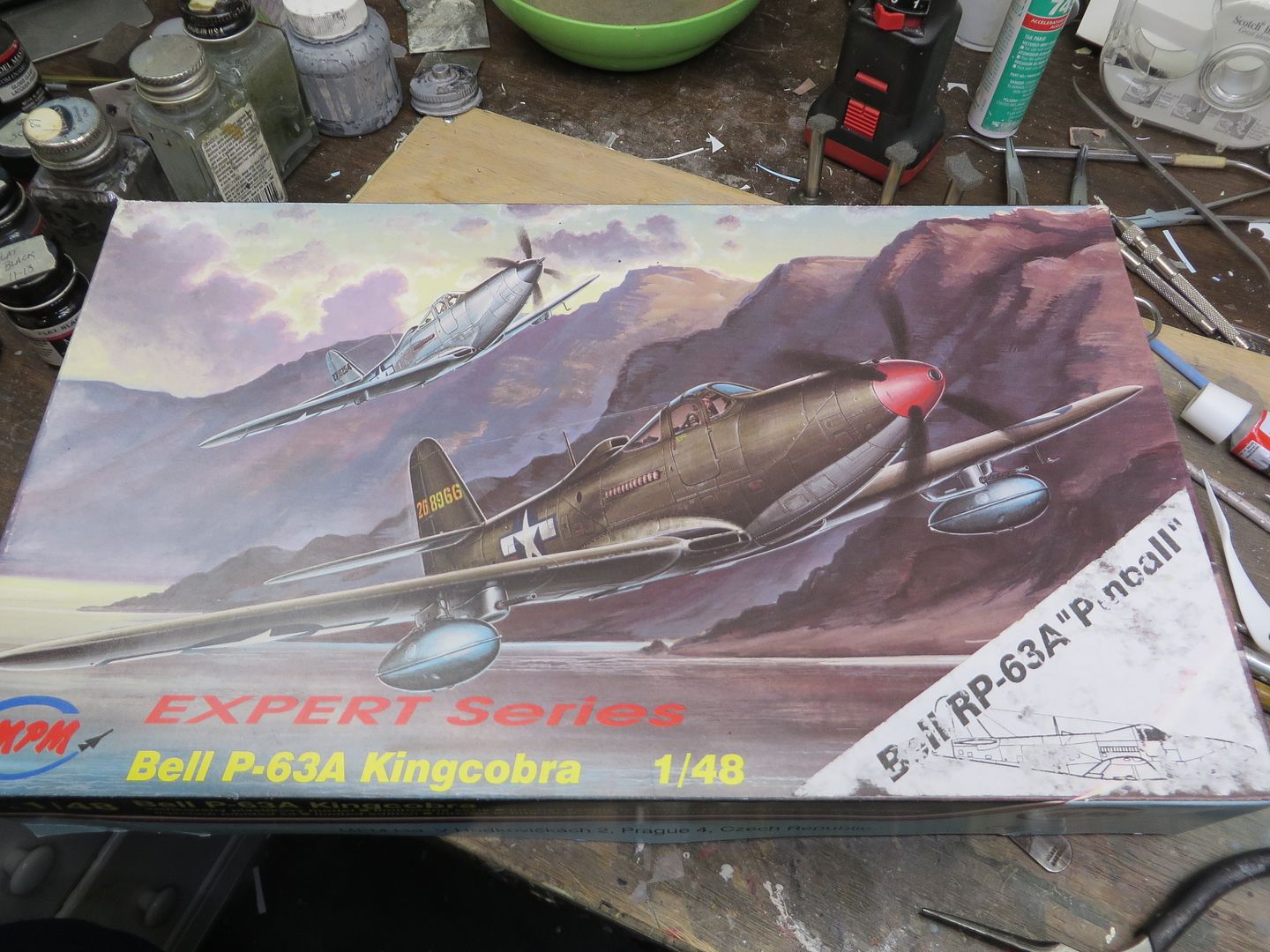

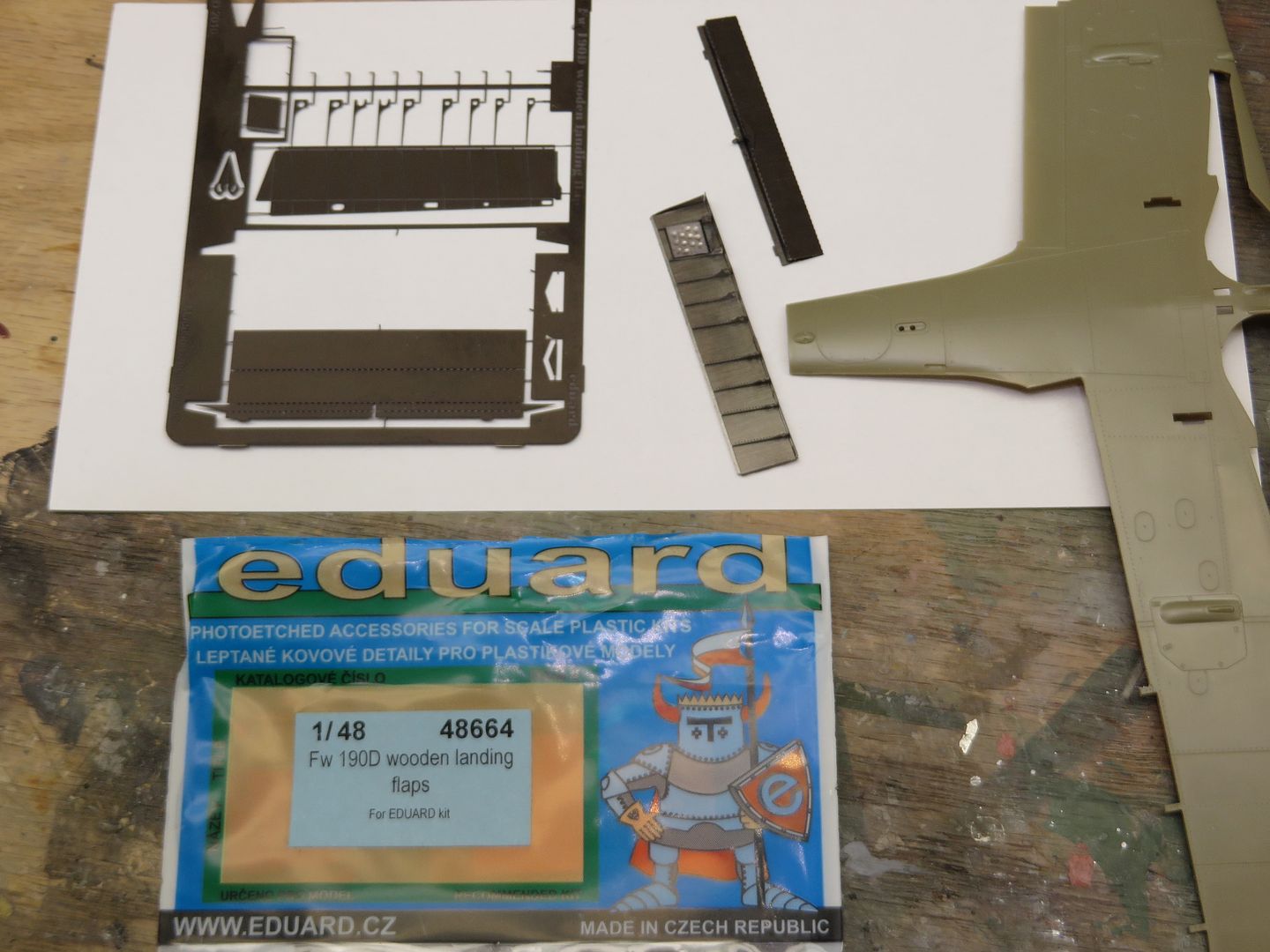

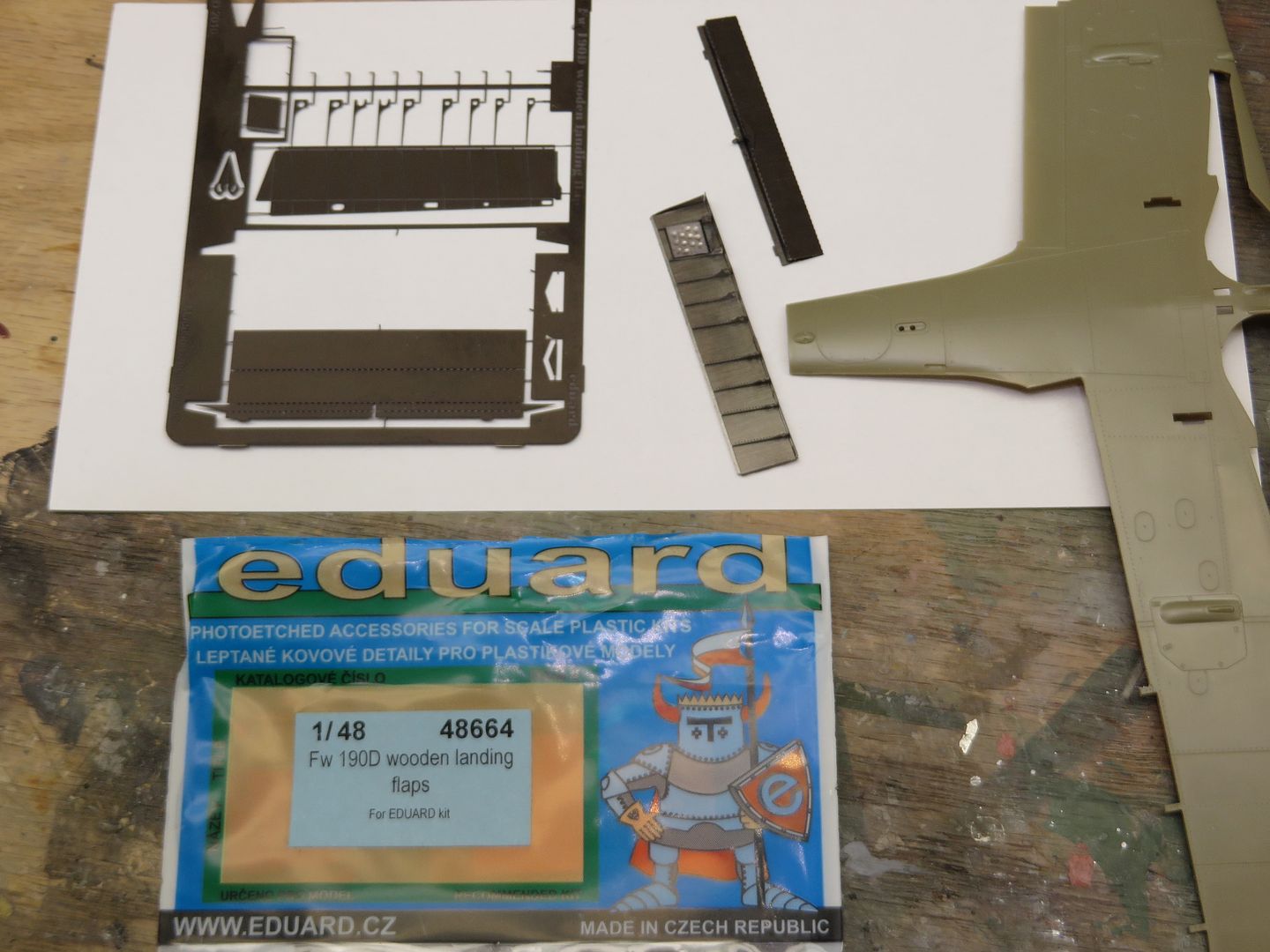

Here is a short review of another of the fine Eduard PE products. I apologize for not building and reviewing this sooner, I was sent this set many months ago.......

Here we have a beautiful set of wooden flaps for the Eduard Fw 190D kit. As most of you know, the manufacturers substituted wood for aluminum on many late-war Luftwaffe machines, and the landing flaps on the Focke-Wulf fighter were redesigned to accomplish this.

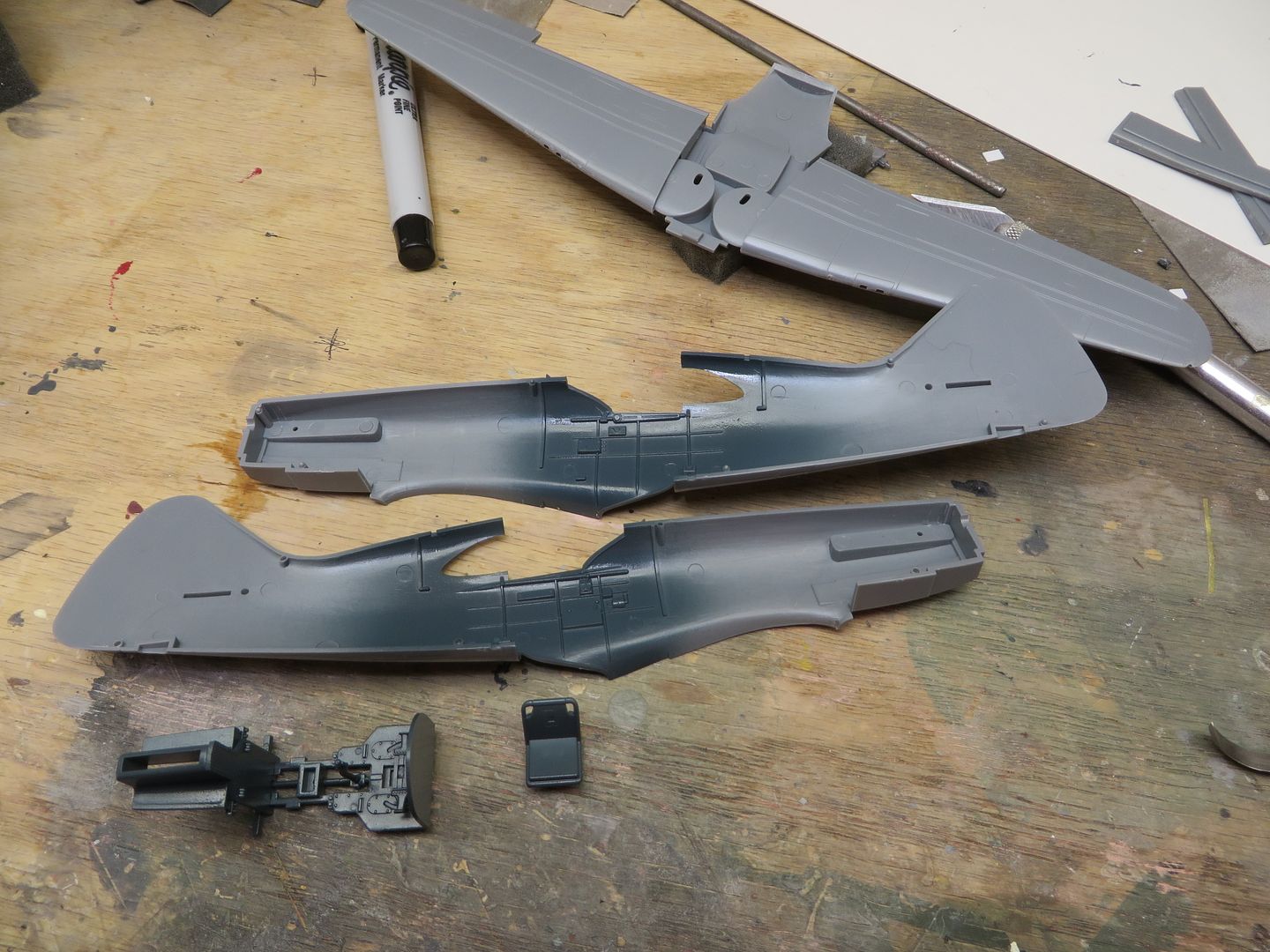

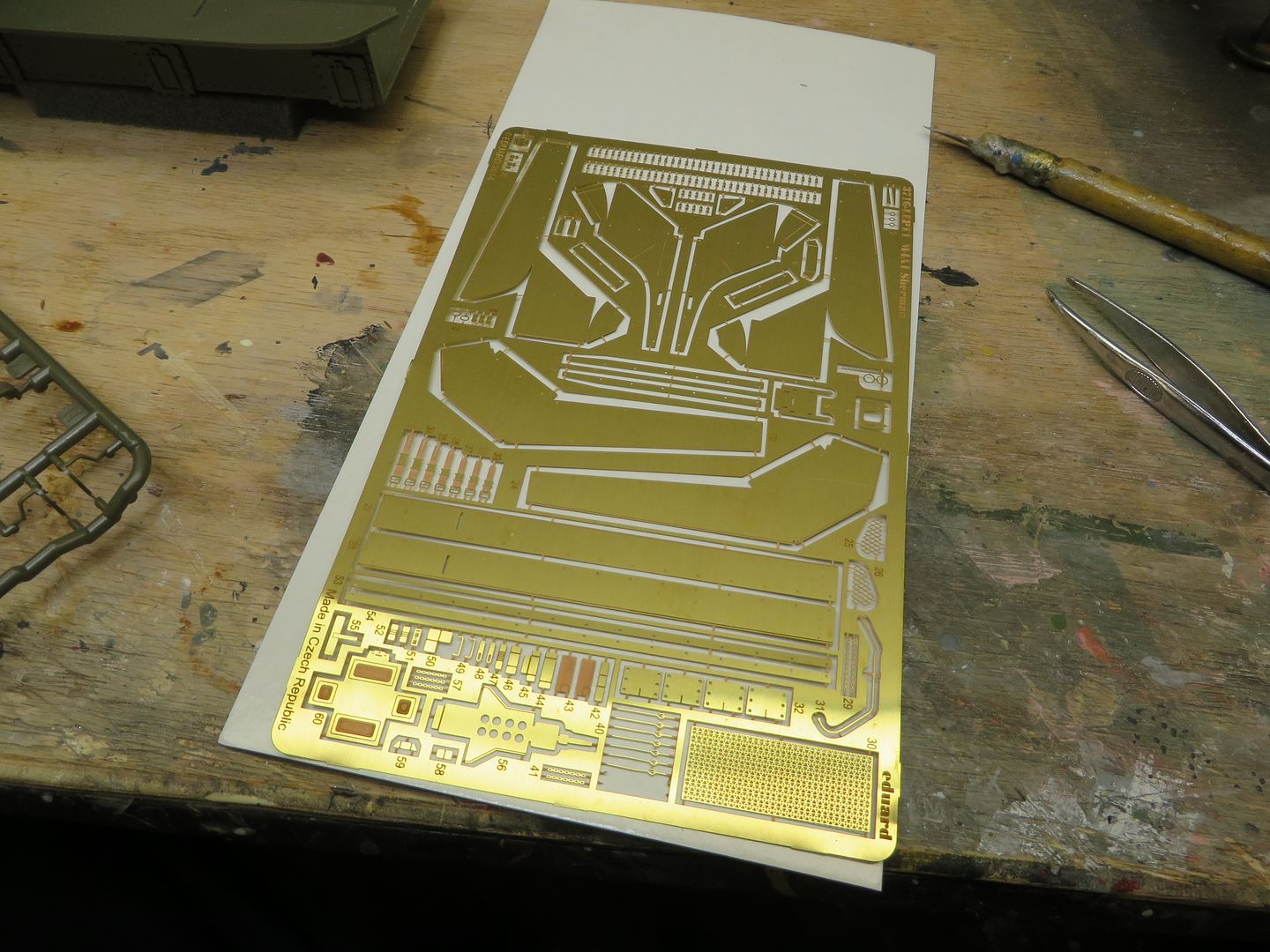

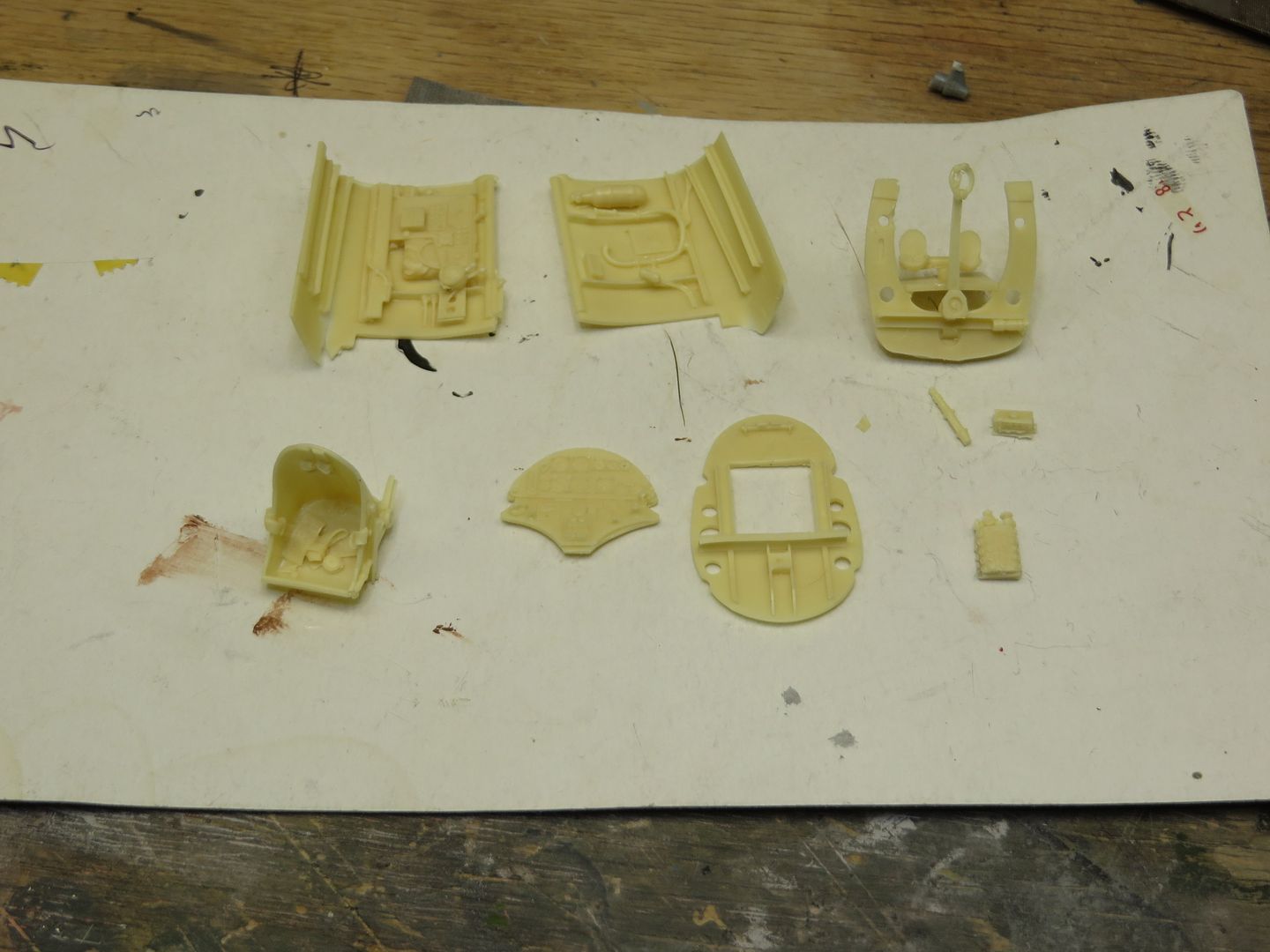

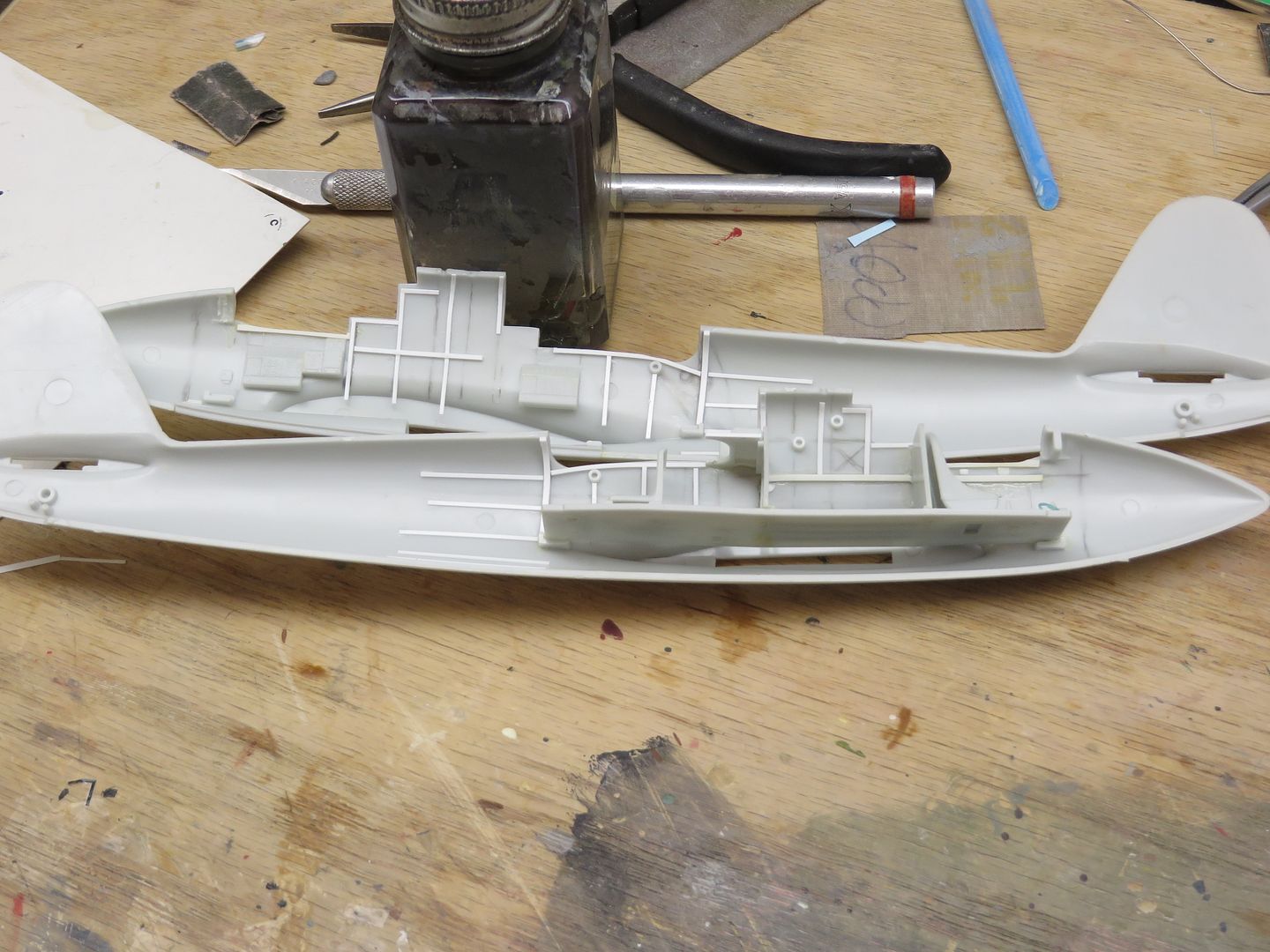

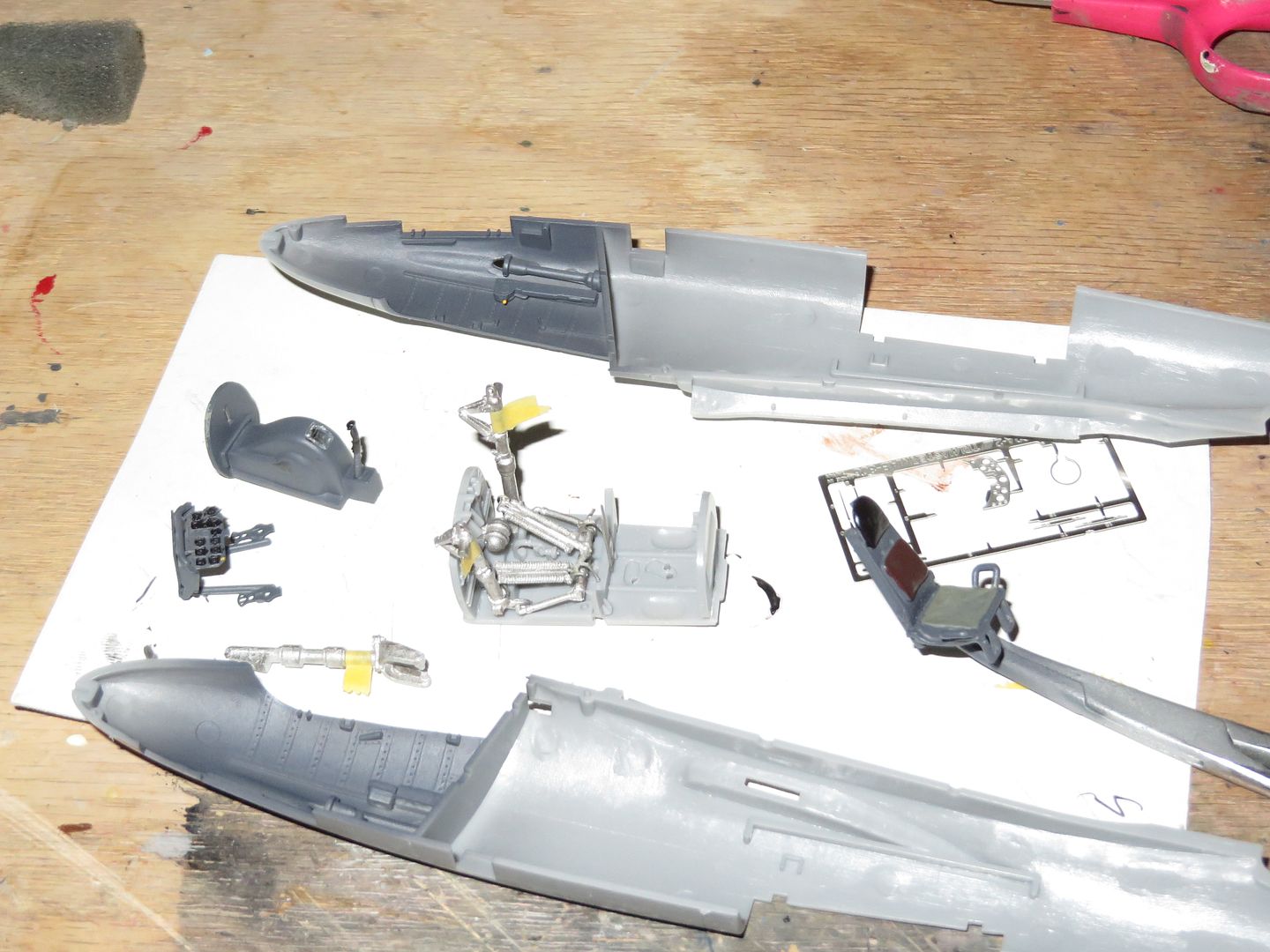

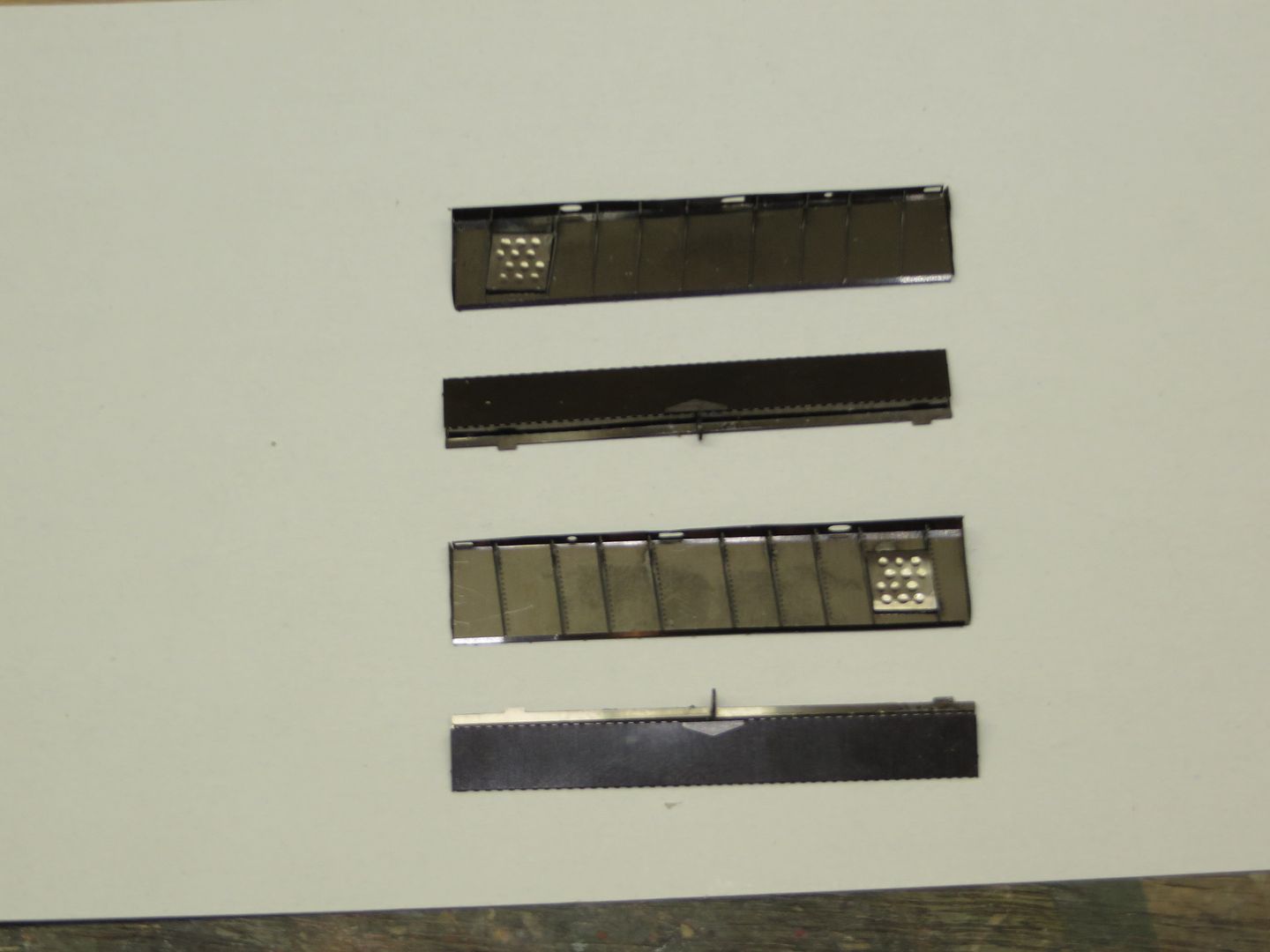

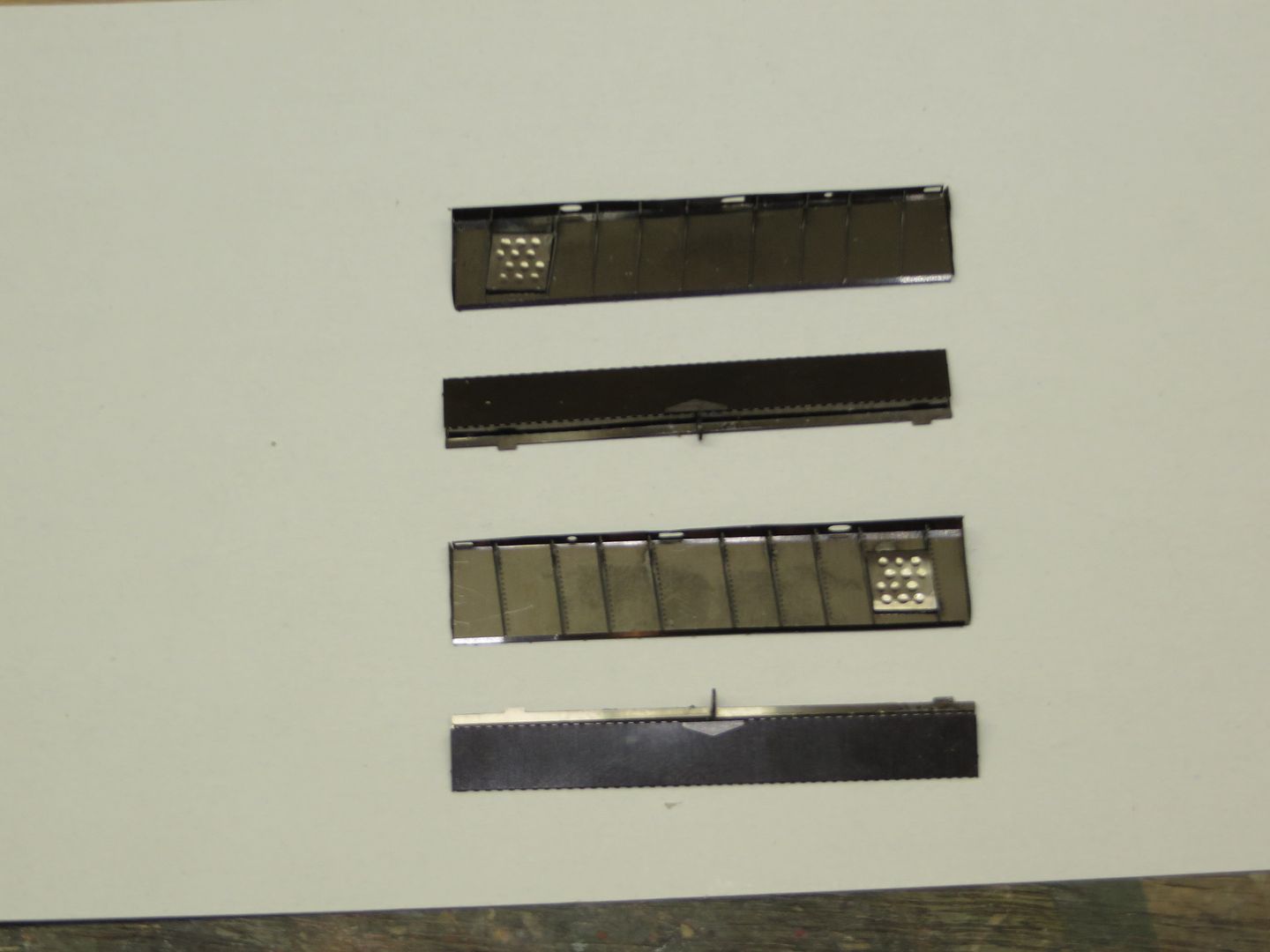

The kit consists of one fret of PE parts and an excellent instruction sheet. The first photo shows one flap and flap-well built up and the other on the fret for comparison. Also, the first flap has been removed from the lower wing part of the airplane kit. This is typical Eduard construction--you just remove the part from the fret and bend the parts as needed. The ribs in the flap-well look complicated but this is quite easy to shape, they bend into position after making the "box" of the larger part. Same with the flap itself--simply bend along the scribed lines, following the instructions, and then use CA glue to bond the part along the joint line. Last step on the PE parts is to add the actuating eccentric to the center of the flap and apply a small trapezoidal doubler to the inner skin.

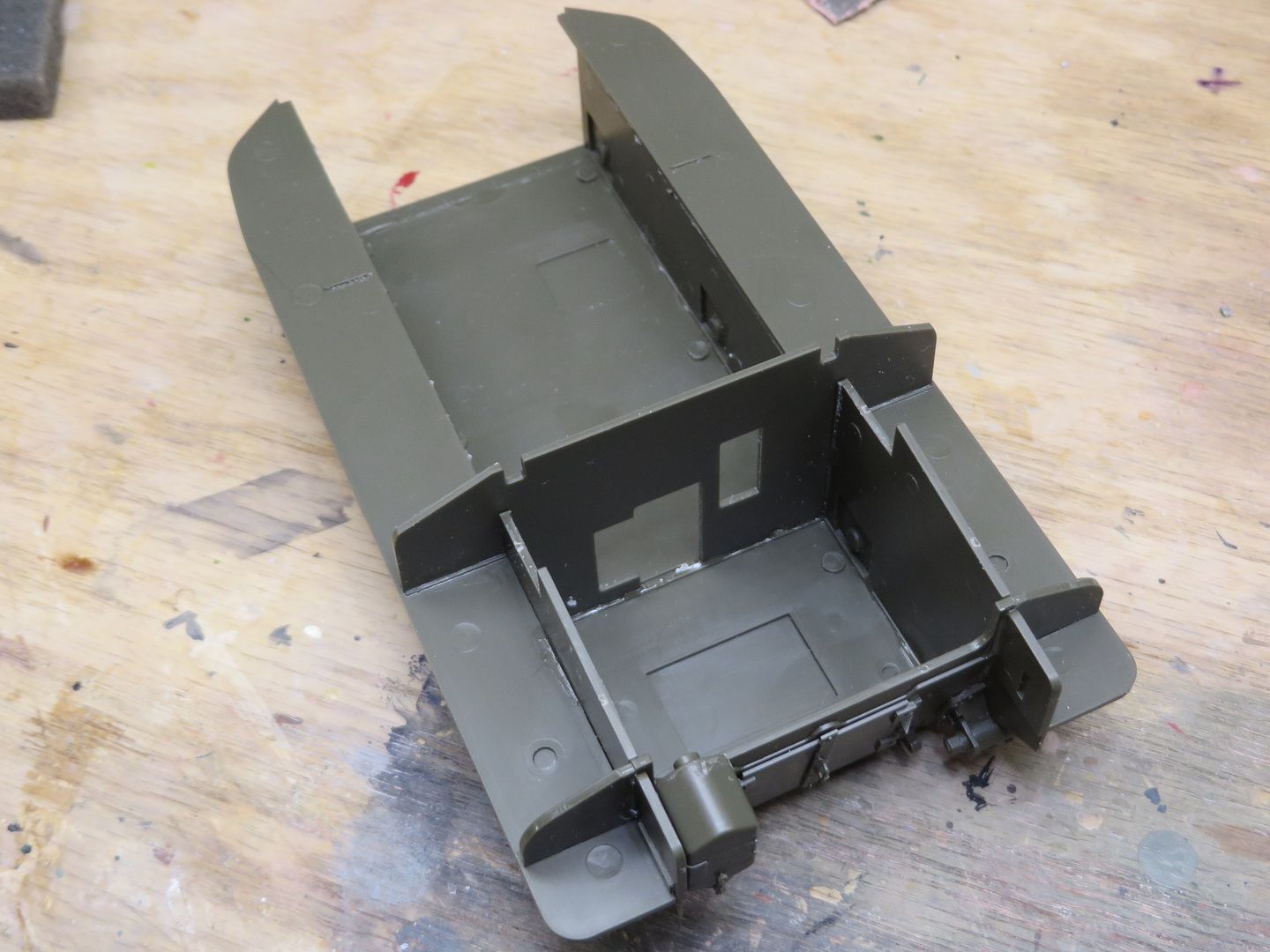

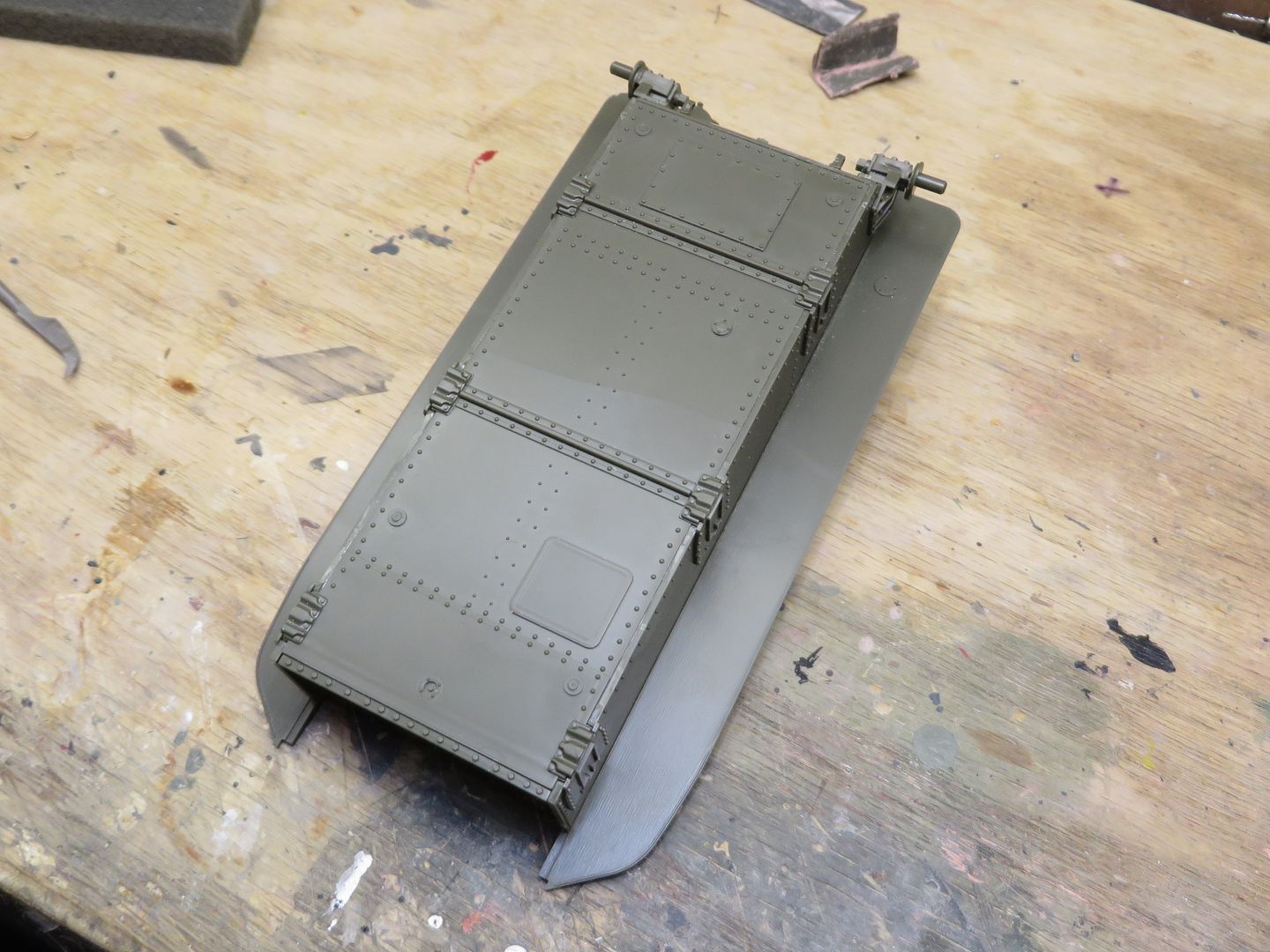

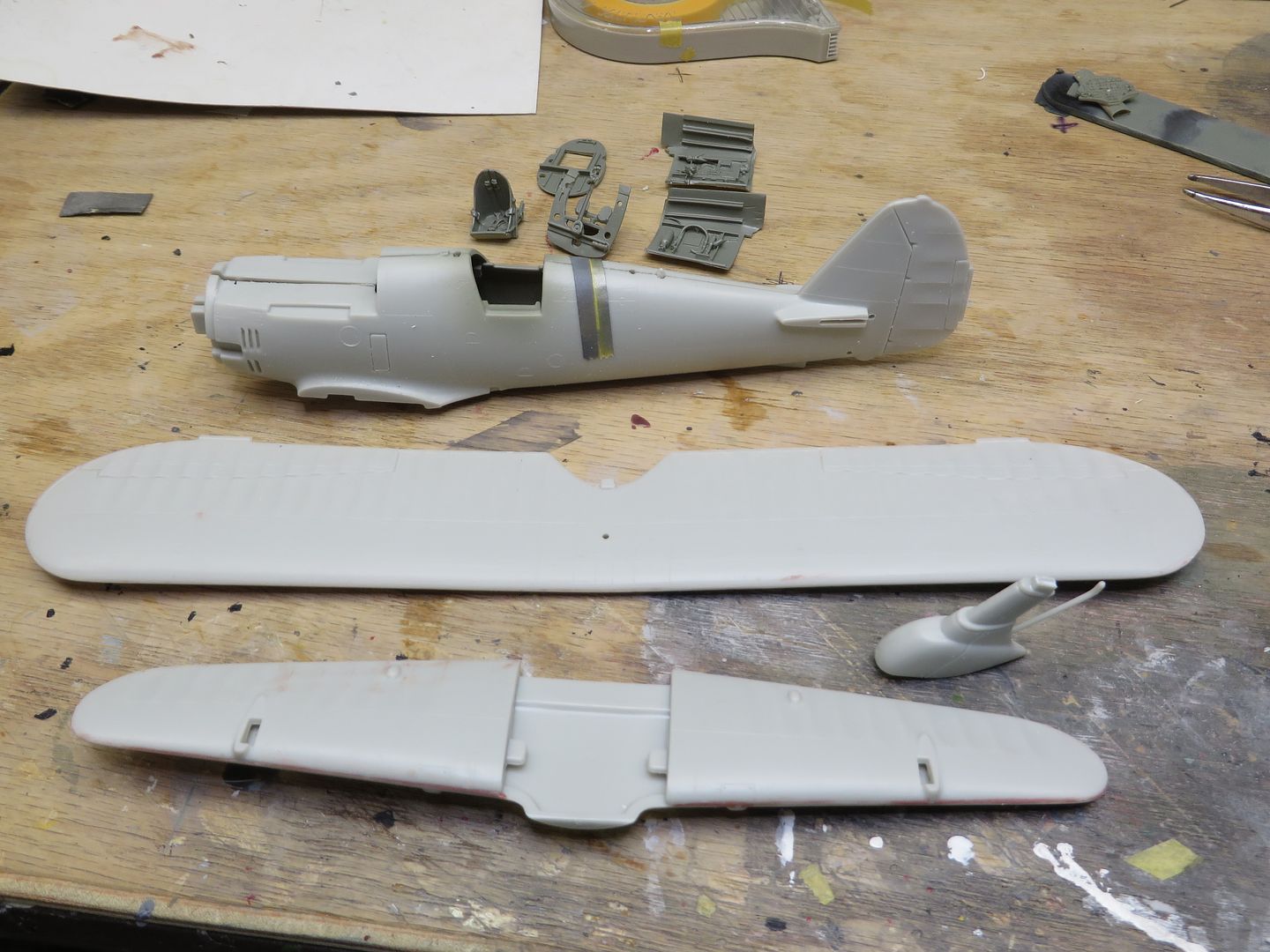

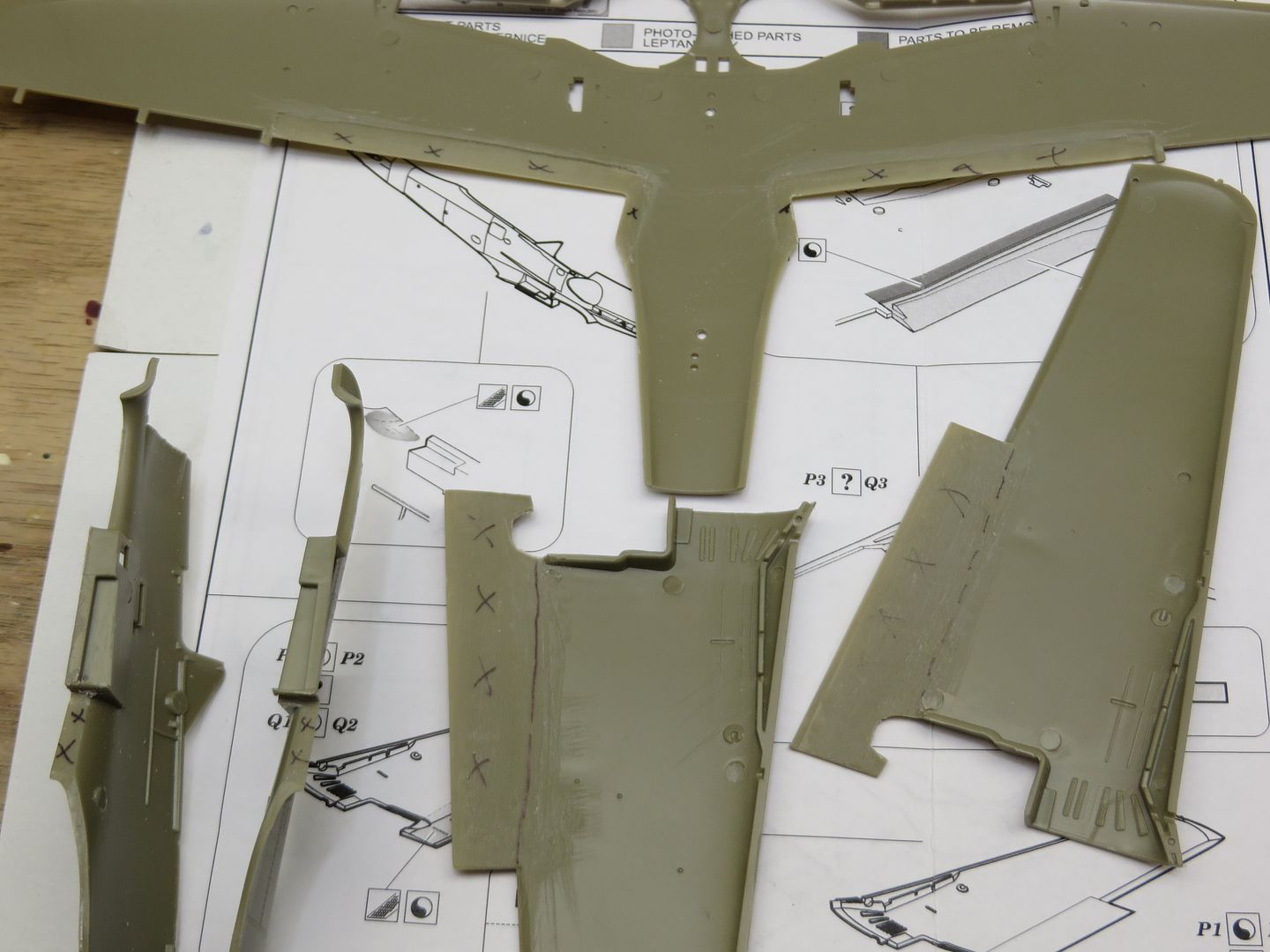

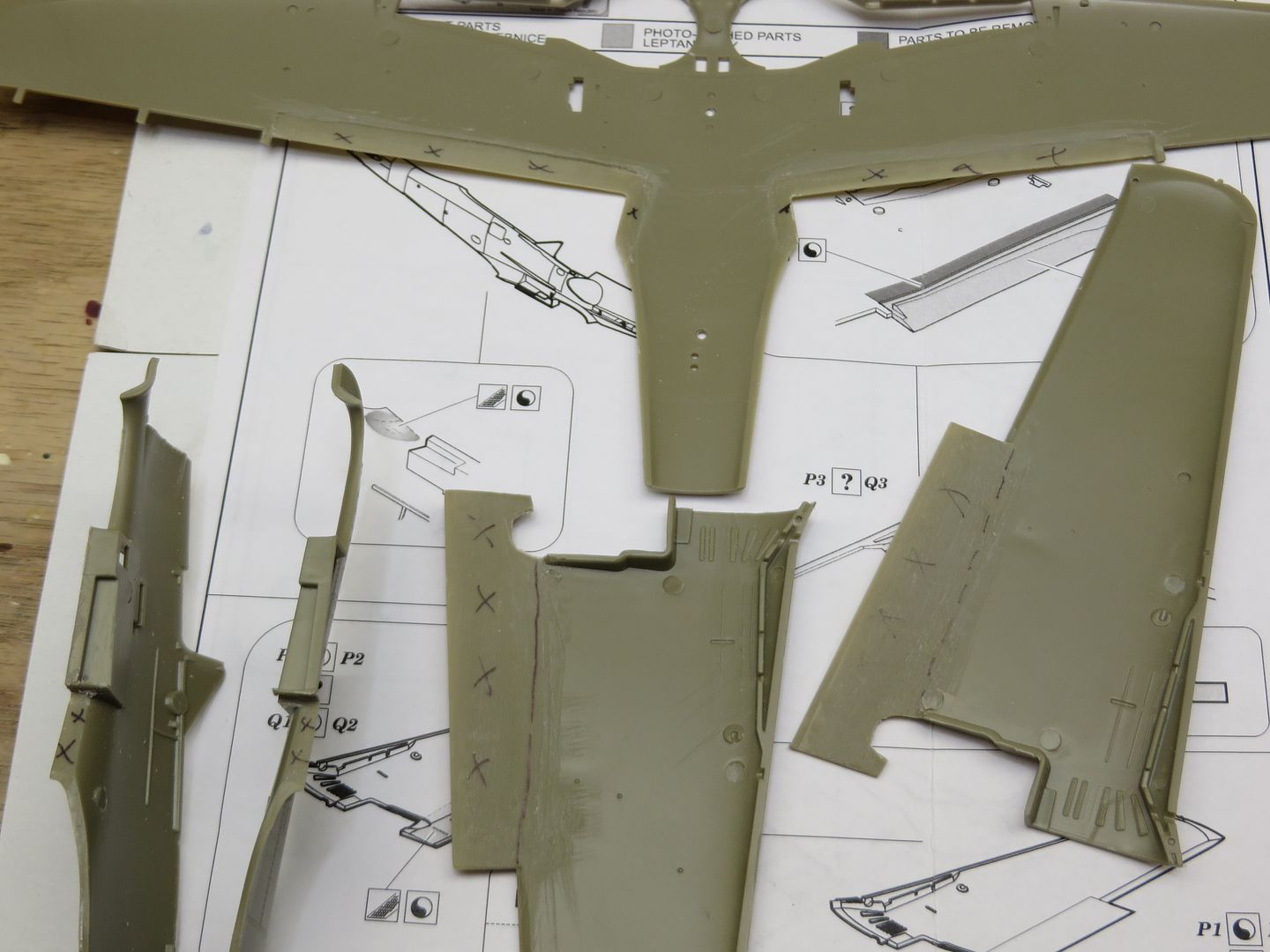

So, the easy part is done! Now we move on to the styrene modifications. These changes are called out on the instructions and consist of thinning the surfaces where the new flap-well will mount. The lower wing requires a deep "shaving" of the plastic and so do both upper wing panels. Eduard has made the flap-wells very deep, just like the real airplane, so this is why you must trim considerable material from the wing parts. Both fuselage halves also must be trimmed where the flap-well will sit as do the inboard gun bay parts. On this photo you can see the trimmed areas marked with small black x letters.

Further updates will come along during aircraft assembly!